|

Your position首頁 > Home > Products > Labeling machine series > HK-620 automatic double rail labeling machine

|

Video:

|

||

|

|

|||

| ●The device can adopt In-line/Off-Line mode. ● XY axis uses servo module, high precision and fast speed. ●It can realize the adsorption and placement of printed package labels. ● Configure the printer to achieve the print and paste function. ● Configure the reader to read or verify the barcode information. ●Z-axis can be attached to different heights on PCBA. ● Standard 8 sets of heads can be attached to 1 - 4 labels at the same time. ●Each set of heads is equipped with independent vacuum detection to prevent leakage and drop. ● Online database system for uploading and feedback barcode information. |

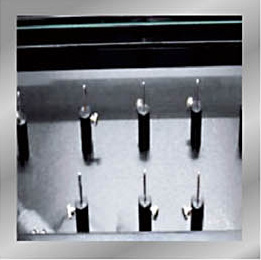

| Standard four The four-head screw has an independent Z-axis with a 60 mm up and down stroke, which is suitable for different height labels and special-shaped devices. |

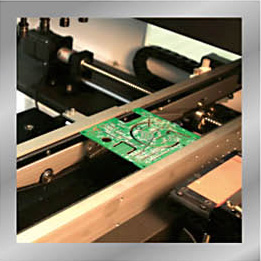

| Roof splint function Equipped with a splint device to ensure the positioning accuracy of each plate, the top plate mechanism is convenient for producing relatively thin and deformed PCBA plates. |

| Track width adjustment Automatic track width adjustment device, when the program is called, the track is automatically adjusted to the program setting width, and the line change is easier. |

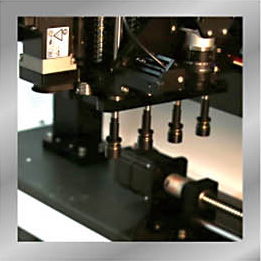

| Quick change of nozzle It can be easily disassembled and equipped without tool nozzles. It can be compatible with JUKI nozzles. It does not need to be customized for individual labels, which is reliable and saves cost. |

| Online flap system The two-track double-segment plate is used to process two PCBs at the same time. The front and back processing does not need to add additional flippers to save space and increase productivity. |

KE- 620 technical parameters

XYZ stroke | 700*450*60mm( -rail) | Maximum labeling range | 500*350mm(-rail) |

700*450*60mm(二rail) | 500*350mm(二rail) | ||

Min:5*5mm | Dimensions | L:1320 W:1620 H:1800 | |

Production capacity | 2000-6000pcs/hr | Host control | Industrial computer |

Labeling angle | Any angle | server system | Mitsubishi servo( 200W ) |

Number of bids | 1-15pcs/Row | weight | 約1100Kg |

Stripping method | Smart feeder | Input power | AC200V/60Hz |

Labeling speed | 0.8-1.5sec/pcs | power consumption | 3Kw |

Identification function | OCR, 1D,2D,MARK,Correction | Air consumption | 1ON1/Min |

positioning accuracy | 0.01 mm | HMI | 10寸Industrial screen |

Screw guide | HIWINPrecision rail | Operating environment | WINDOWS 7 |

Track width adjustment | Automatic tuning | Permission distinction | password |

CopyRight ? Suzhou Hongkai Electronics Co., Ltd. sitemap ICP 19076189